Sensor-based electronics are at the heart of modern technology — from smart lighting systems to industrial automation. Among these sensors, the Light Dependent Resistor (LDR) is one of the simplest and most widely used components for light sensing applications. However, selecting the right LDR is just the first step. The quality of the final product heavily depends on the expertise of your PCBA manufacturer. In this article, we explore the path from LDR selection to final assembly and highlight the critical role a PCBA manufacturer plays in ensuring reliable, high-performance sensor-based devices.

What is an LDR?

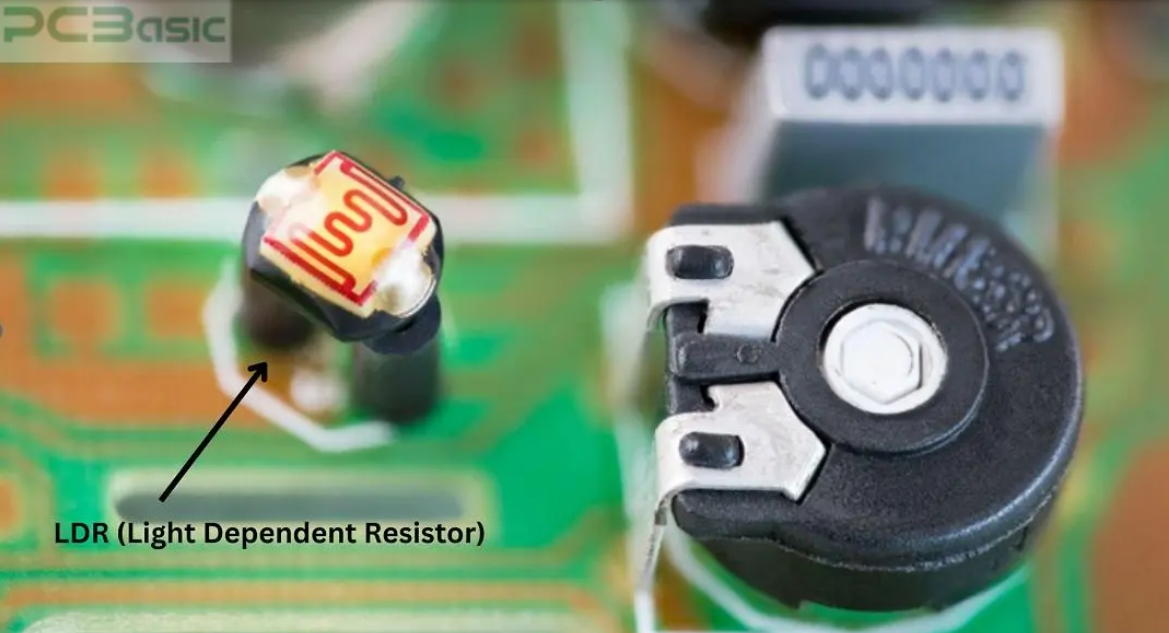

An LDR (Light Dependent Resistor) is a variable resistor whose resistance changes according to the amount of light falling on it. In darkness, the resistance is high, while exposure to light significantly lowers the resistance.

Key Applications:

- Automatic streetlights

- Solar garden lights

- Smart lighting and shading systems

- Light intensity meters

- Camera light metering

Selecting the Right LDR for Your Project

Choosing an LDR involves more than just picking a part number. Key factors to consider include:

- Spectral sensitivity: Ensure it matches the light wavelengths relevant to your application.

- Response time: Some applications need faster response to changing light levels.

- Resistance range: Verify that the dark and light resistance values suit your circuit design.

- Operating temperature: Consider environmental conditions, especially for outdoor or industrial devices.

- Size and packaging: The LDR must be compatible with your PCB layout.

A professional PCBA manufacturer can assist in component selection, recommending reliable suppliers and suitable alternatives to optimize cost, availability, and performance.

The Role of a PCBA Manufacturer in LDR-Based Projects

An experienced PCBA manufacturer contributes to your project’s success in multiple ways:

Design for Manufacturability (DFM) Guidance

Your PCBA partner will review your design files to ensure LDR placement and routing are optimized for performance and mass production.

Precision SMT or Mixed Assembly

If your board combines SMT components and through-hole LDRs, the manufacturer will integrate both processes seamlessly, ensuring high assembly quality.

Sourcing Reliable LDRs

A strong PCBA manufacturer has established relationships with trusted component suppliers, reducing the risk of counterfeit or low-quality parts.

Quality Control

LDR-based boards require thorough testing. Your PCBA partner will apply:

- AOI (Automated Optical Inspection) for solder quality

- Functional testing to verify LDR response

- Environmental stress screening if needed

Scalability

From prototypes to large production batches, the manufacturer provides flexible solutions to match your project’s stage and volume.

Why Partnering with the Right PCBA Manufacturer Matters

Poor component handling or assembly errors can result in:

- Inaccurate light sensing

- Premature component failure

- Reduced product lifespan

- Increased warranty costs

By working with a PCBA manufacturer experienced in sensor-based assemblies, you gain:

- Enhanced product reliability

- Shorter time-to-market

- Better cost control

Conclusion

The journey from LDR selection to a finished, high-quality sensor device relies on collaboration with a capable PCBA manufacturer. Whether you are designing smart home lighting, industrial monitoring systems, or consumer electronics, choosing the right manufacturing partner ensures your product meets both functional and commercial expectations.

YOU MAY ALSO LIKE: Tesla Humanoid Robot: Opening a New Chapter in Future Human-Machine Collaboration